ExtractionTek Stainless

ExtractionTek Stainless designs, engineers, and fabricates the most innovative stainless-steel extraction and processing solutions in the cannabis market. With vast in-field manufacturing and engineering experience in food, pharma and cryogenic industries, our team puts safety and quality at the forefront of everything we do.

At ExtractionTek Stainless, our goal is to offer premium customer service and tech support. By selecting the appropriate training to meet your needs, you’ll accelerate your organization’s success in the fast-paced cannabis processing market. Your earnest efforts to get to this point are recognized. Let the ExtractionTek team set you up for success to exceed your processing goals.

We provide both on-site and virtual training services to make sure you know how to operate our systems safely and correctly.

ExtractionTek Is Proud to Announce the Acquisition of Delta Separations

Two leaders in the Cannabis Extraction industry have come together as one! ExtractionTek Stainless, the leader in Cannabis Extraction, is proud to announce the launch of our Delta Separations Sales, Support and Service beginning September 1st, 2023. ETS will now be offering the best selling designs in Ethanol Extraction within the time tested ETS Sales and Support model. We currently have all centrifuge designs in stock and available to our clients at discounted introductory pricing while initial supplies last. In stock parts, pieces and bearing assemblies are available from a member of the #ETSGang with overnight shipping available in most cases. Our Delta Separations product pages are still under construction, but all information and data sheets will be available soon!

Introducing The MeP-XLE

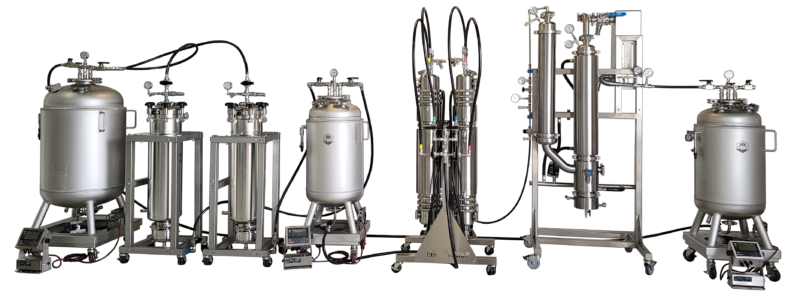

The Modular Extraction Platform XLE (The MeP XLE) is the industry’s leading closed-loop solution for ultra high-capacity extraction operations. Offering a range of material capacity from 50 to 300 Liters The XLE offers operators the flexibility and scale needed to succeed in the modern Cannabis industry. This new design includes the HFFE Hydrocarbon Falling Film Evaporator manufactured by ETS, allowing for consistent and efficient solvent recovery. The leader in Hydrocarbon Extraction Equipment has once again raised the bar and redefined efficiency for the extraction industry.

Butane & Propane Extraction Equipment

Ethanol Extraction Equipment

Why Choose Us?

ExtractionTek Stainless, since inception in 2011, has set itself apart from the rest of the cannabis extraction industry in many ways. SAFETY, QUALITY, EFFICIENCY, and SERVICE have always been and will remain, THE PILLARS that distinctly differentiate ETS from the others. U.S. STEEL, ENGINEER PEER-REVIEWED, ASME, C1D1, 3-A SANITARY COMPLIANT. CONTACT US TODAY to find out why your next UPGRADE should be an ETS!

Domestic Steel & Lead Times

In 2011, “Creating an Industry” meant going above and beyond in every respect. First and foremost -quality of build. Early on, there was value in telling regulators and fire departments our hydrocarbon extraction machines were made of U.S. Steel. This helped gain trust and establish legitimacy considered absent from hydrocarbon extraction machine manufacturers of the time.

Today, geo-political and global supply chain issues are causing uncertainty for manufacturers relying on foreign steel. In our space it’s become increasingly rare for manufacturers to use Domestic Steel – giving way to margins over quality. Since day one we’ve sourced our steel domestically for one reason and will continue to do so for that reason. QUALITY.