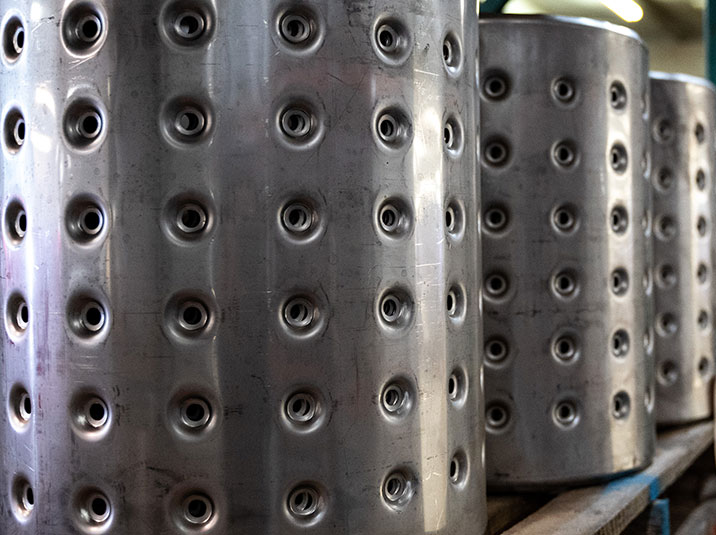

The Heated Filtration Skid filters the wash solution through a 1um particulate filter and heat exchanger, filtering out any unwanted particulates while heating the solution so it is primed for the Solvent Recovery Skid

Key Features

Throughput

The Heated Filtration Skid (HFS) is a fully automated solution that offers filtration and solution heating rates of 10 gallons per minute, continuously. This design will significantly imporove your operations time between ultra-cold extraction and solvent recovery.

Footprint

With a base footprint of roughly 10′ x 8′ The EFR was designed to fit in all current and future ethanol extraction facilities. The manageable footprint makes it easy for a single technician to operate.

SYSTEM DIMENSIONS: 60″ x 50″ x 69″

Certified

The HFS is third party engineer Peer Reviewed. The control panel is UL Listed and all electrical components are CID2 compliant. U.S. Steel. ASME. GMP compliant.