In 2011, ExtractionTek introduced the first commercially sized and peer reviewed closed-loop hydrocarbon extraction system, The 1300. From the beginning it was important our machines be made of U.S. Steel and built in Colorado. Our patented design, now in production for over 9 years, is responsible for more than 6 million extraction runs. The 1300 is the most tried and true design in the hydrocarbon extraction space. ExtractionTek Solutions specializes in providing companies with safe and reliable extraction equipment. The Design that Created an Industry.

Versatility

The 1300 is able to use n-butane, propane, or blended solvents, allowing the production of more end products than machines using other solvents.

Throughput

The 1300 has a material capacity of 5 liters and accommodates up to 2 lbs of source material per run. Runs typically take 20 minutes with propane and 40 minutes with butane. Other key variables include recovery pump being utilized and temperatures.

Quality

The 1300 is comprised of U.S. Steel and comes equipped with a Chromite 3000 hot water recirculating system to monitor and maintain constant temperatures throughout the recovery process.

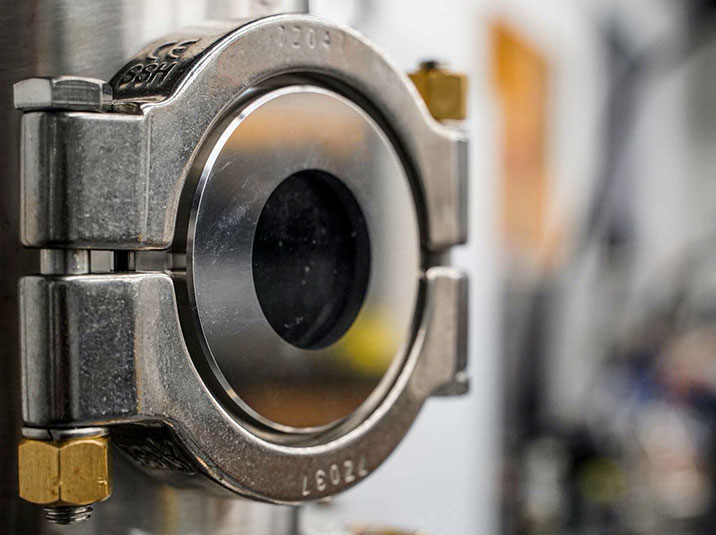

Certified

The 1300 meets or exceeds all industry listed standards: ASME SECTION Viii, IFC, NFPA 58, 3-A Sanitary Standard, CLASS I DIVISION 1, NSF and UL21.

Versatility

The 1300 is able to use n-butane, propane, or blended solvents, allowing the production of more end products than machines using other solvents.

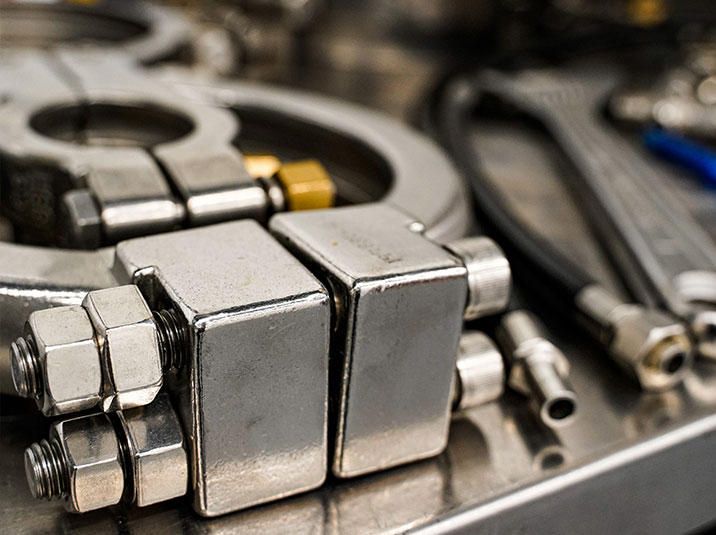

Footprint

With a 2’ x 2‘ footprint, all of The 1300 columns, vessels, and connections can be removed and reassembled for thorough cleaning, maintenance, and storage.