The Modular Extraction Platform XLE (The MeP XLE) is the industry’s leading closed-loop solution for ultra high-capacity extraction operations. Offering a range of material capacity from 50 to 300 Liters The XLE offers operators the flexibility and scale needed to succeed in the modern Cannabis industry. This new design includes the HFFE Hydrocarbon Falling Film Evaporator manufactured by ETS, allowing for consistent and efficient solvent recovery. The leader in Hydrocarbon Extraction Equipment has once again raised the bar and redefined efficiency for the extraction industry.

ExtractionTek’s ASME Titan Material Column offers operators a large capacity format to perform extractions at scale. This standalone jacketed modular unit can be ran in configurations from 50 Liters – 300 Liters allowing for large scale cannabis and hemp processing without the need for extensive retro fitting in your current facility.

Fully integrated into the design of The XLE is ExtractionTek’s Hydrocarbon Falling Film Evaporator (The HFFE.) This large scale solvent recovery system offers the speed operators demand to process cannabis and hemp based oils consistently and quickly. This in-line recovery solution provides up to 6 pounds of solvent recovery per minute.

Flexible filtration on demand. The integrated CRC columns included with The-XLE provide a full shift of on demand filtration that can be routed through our manifold based CRC columns. This allows an operator to direct the flow of oil through a series of different filtration media, or to simply bypass filtration entirely.

Versatility

The MeP XLE provides the flexibility to run Propane, Butane, and blended solvents giving the operator the ability to produce ALL of today’s popular concentrated retail products.

Technology

The MeP XLE utilizes passive solvent recovery and in-line color remediation to produce high quality cannabis extracts in scale consistently.

Capacity

The MeP XLE Titan Extraction Vessels can be setup in various configurations that offer between 50 – 300 Liters of material capacity per extraction.

Safety

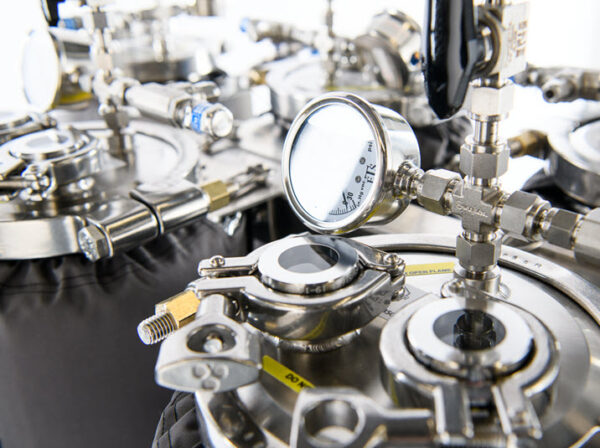

The MeP XLE is 3rd Party Engineer Peer Reviewed by Pressure Safety Inspectors L.L.C. This design includes compliant connections and gaskets for safe operation at ultra low solvent temperatures.

Integrity

Proudly Manufactured in Colorado, ExtractionTek refuses to compromise on material quality. The MeP XLE and all units at ETS are built using U.S. Steel coupled with the highest quality components.

Flexible Footprint

Measuring a total of 130 square feet, The MeP XLE footprint is designed with flexibility in mind. This unique skid design can be configured to fit in most existing extraction booths.