The Hydrocarbon Falling Film Evaporator (The HFFE) offers Extraction Operators the option to speed up recovery using our Peer Reviewed Speed Tested Hydrocarbon Falling Film Evaporator Technology. The HFFE can be configured for either batch or continuous processing allowing operators the speed they demand utilizing the industry’s FASTEST Butane and Propane recovery option.

The leader in Light Hydrocarbon Equipment has once again raised the bar and redefined efficiency for the extraction industry.

Capacity

The HFFE offers operators the ability to keep up with all modern hydrocarbon extractors recovery needs, regardless of material capacity. Recovery speeds average 3-6 pounds per minute depending on configuration.

Footprint

Measuring 26 square feet (8′ x 3.25′), The HFFE footprint is designed to fit your current extraction room infrastructure without the need of costly expansion.

Speed

The HFFE provides the flexibility to recovery Propane, Butane, and blended solvents utilizing Falling Film technology offering recovery at 4-8 pounds per minute.

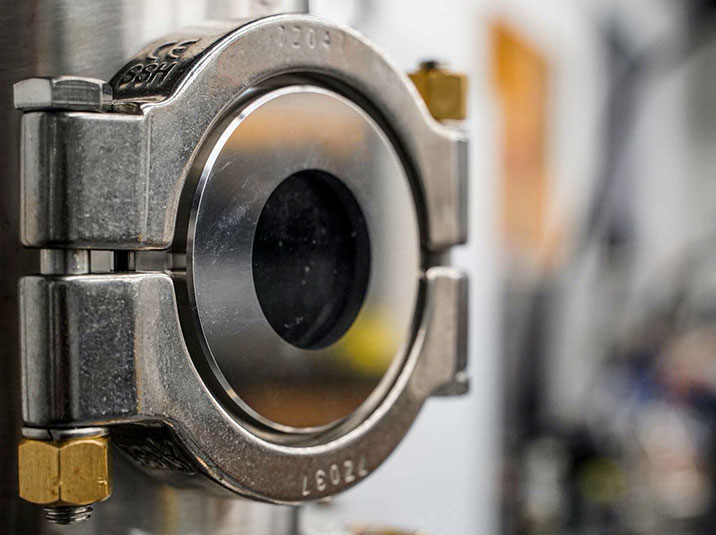

Integrity

Proper time and testing were put into this design to assure every operator can realize the top recovery speeds available by configuration. Every HFFE is proudly manufactured in the USA in Denver, Colorado.

Turnkey

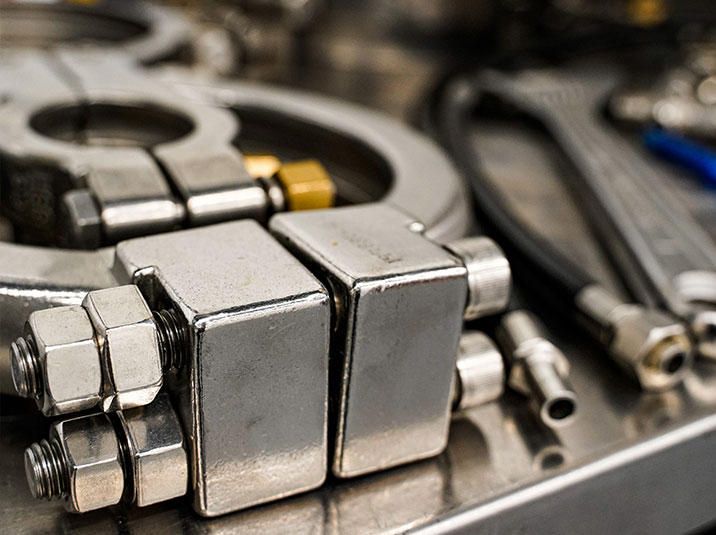

Out of the box, The HFFE comes with everything needed to run the evaporator without the hassle of sourcing ancillary equipment.

Certified

The MeP meets or exceeds all industry listed standards: ASME SECTION Viii, CRN, IFC, NFPA 58, 3-A Sanitary Standard, CLASS I DIVISION 1, NSF and UL21.