The Dual Stage Skid is a continuous feed add on that runs from the outlet pump of the SRS. This system preps crude oil for distillation by degassing, devolatizing, and decarboxylating the crude oil.

Key Features

Closed Loop System Designed for Safety

100 or 300 LPH Continuous Decarboxylation Options

99.9% Decarboxylation Conversion and Solvent Removal

Rising Film Technology for Minimal Cannabinoid Degradation

Touch Screen Operated

Ethanol and Heptane Compatible

Custom Stand-Alone Options

UL Hazardous Location Controls with Air Purged Control Panel

Third Party Engineer Peer Reviewed

Proudly Engineered and Fabricated in Denver, Colorado, USA

GMP Compliant

Throughput

The Dual Stage (DS) is able to process 100-300 Liters per Hour using continuous decarboxylation. This process offers a 99.9% decarboxylation conversion and full solvent removal.

Footprint

With a base footprint of roughly 4.5‘ x 3’ The DS was designed to fit in all current and future ethanol extraction facilities. The manageable footprint makes it easy for a single technician to operate.

100 LPH System: 52″ x 30″ x 86″

300 LPH System: 52″ x 30″ x 92″

Certified

The DS is third party engineer Peer Reviewed. The control panel is UL Listed and all electrical components are CID2. U.S. Steel. ASME. GMP compliant.

Includes

Training and Install Support

C1D2 Ul Listed Components

Discharge Pumps for Decarboxylated Crude Oil and Cold Trap Solution

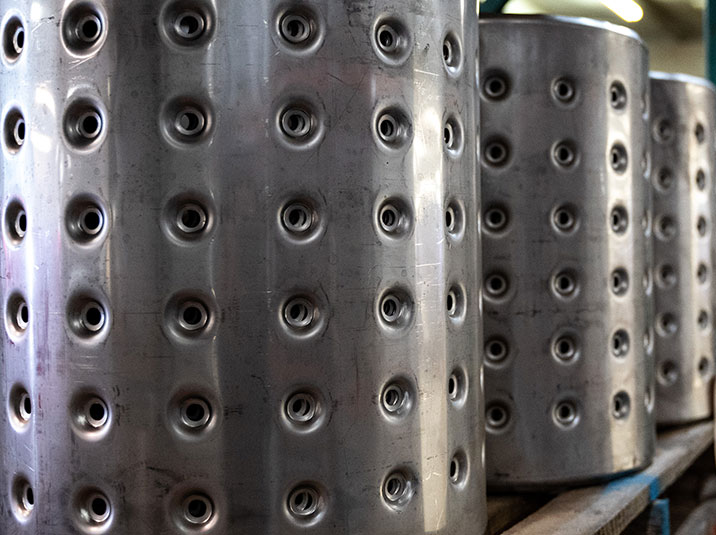

Tube and Shell for Main Decarboxylation Column

Plate Exchanger for Ethanol Condensing

Ethanol Condensing: MTA Chiller

Ethanol Evaporation: Sussman Steam Boiler

Utility Requirements

Control Panel Power 208V-240V (3 Phase)

Ancillary Options: 208V, 240V or (3 Phase)

C1D2 Rated Environment

Ancillary Plumbing Supplied by Licensed Technician per Local and National Codes

Air Compressor Providing 8 CFM at 30 PSI

System Size

100 LPH System: 52″ x 30″ x 86″

300 LPH System: 52″ x 30″ x 92″