The Extraction Filtration Skid is the only closed loop all-in-one solution on the market. This platform encompasses extraction, filtration, and recovery. We use a batch style centrifugal extraction process, 3 stage filtration down to .5 micron, and rising film technology recovery.

Key Features

Throughput

The EFR is able to process 30-60 lbs of Biomass per hour with batch run times of 15 minutes. Not only is The EFR designed to run FAST, but the BUILD QUALITY will ensure your machine will operate safely and efficiently for years to come.

Footprint

With a base footprint of roughly 10′ x 8′ The EFR was designed to fit in all current and future ethanol extraction facilities. The manageable footprint makes it easy for a single technician to operate.

SYSTEM DIMENSIONS: 160″ x 80″ x 84″

Certified

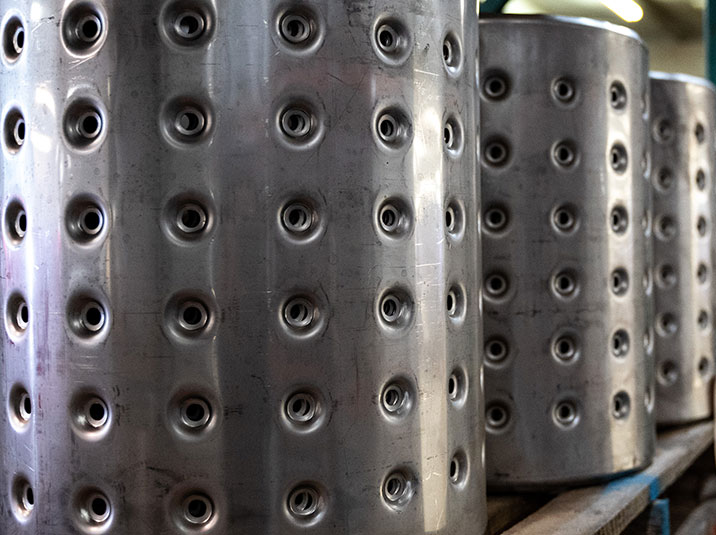

The EFR is third party engineer Peer Reviewed. The control panel is UL Listed and all electrical components are CID1. U.S. Steel. ASME. GMP compliant.