The Solvent Recovery Skid, offered in two options (100L/hr & 300L/hr), takes the heated wash solution from the Heated Filtration Skid and evaporates the ethanol separating it from the cannabinoids. This skid produces crude oil and recovers clean ethanol which can be used again in the extraction process.

Key Features

Throughput

The SRS designed to RECOVER SOLVENT FAST, 100L/hr or 300L/hr (depending on model) and feed rate (up to) 100/1/hr.

Footprint

With a base footprint of roughly 8′ x 4′ The SRS was designed to fit in all current and future ethanol extraction facilities. The manageable footprint makes it easy for a single technician to operate.

100 LPH System: 96″ x 43″ x 95″

300 LPH System 113″ x 43″ x 100″

Certified

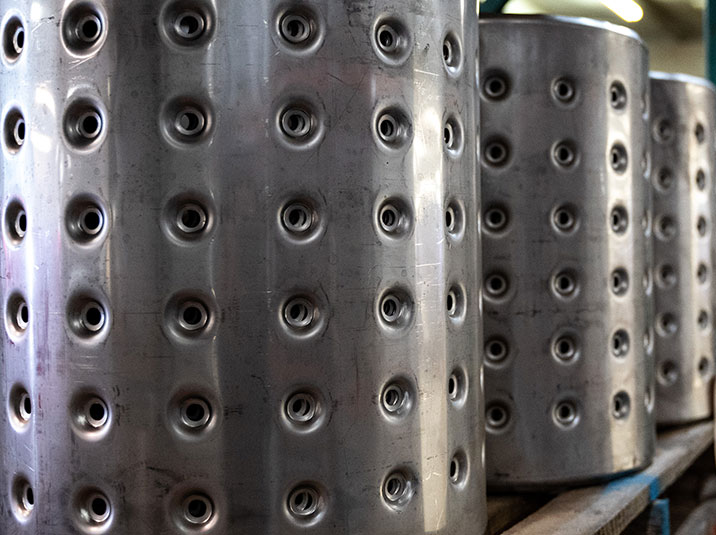

The SRS is third party engineer Peer Reviewed. The control panel is UL Listed and all electrical components are CID1. U.S. Steel. ASME. GMP compliant.