The Alcohol Extraction Skid is designed to separate cannabinoids from the rest of the plant material (biomass) using -40° C food grade ethanol to strip off the desired compounds from the plant material. This process creates a “Wash” solution of cannabinoid content and alcohol. Extracting at a cold temperature eliminates the need for winterization and prevents undesirable compounds such as lipids, fats, waxes, and chlorophyll from being extracted from the biomass in the initial stages of the process.

Key Features

Throughput

The AES is able to process 120 lbs of biomass per hour with batch run times of 30 minutes. This Dual-Centrifuge design offers maximum throughput without sacrificing on operational flexibility.

Footprint

With a base footprint of roughly 10′ x 5′ The AES/C was designed to fit in all current and future ethanol extraction facilities. The manageable footprint makes it easy for a single technician to operate.

SYSTEM DIMENSIONS: 120″ x 60 x 86″

Certified

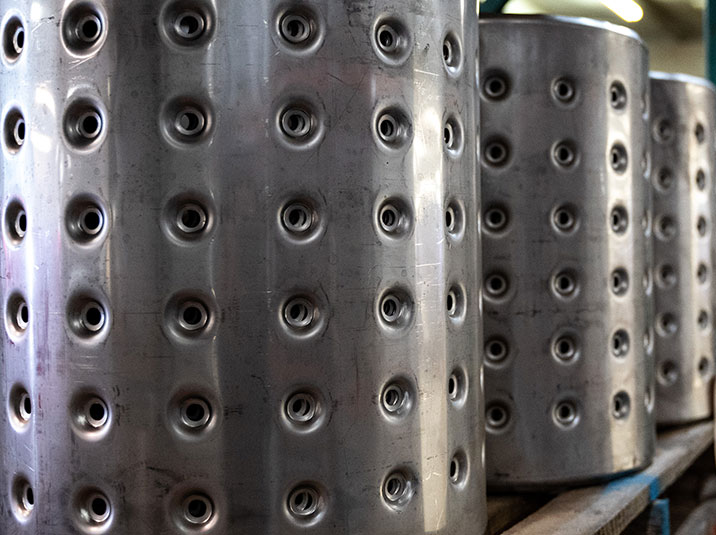

The AES/C is third party engineer Peer Reviewed. The control panel is UL Listed and all electrical components are CID2. U.S. Steel. ASME. GMP compliant.